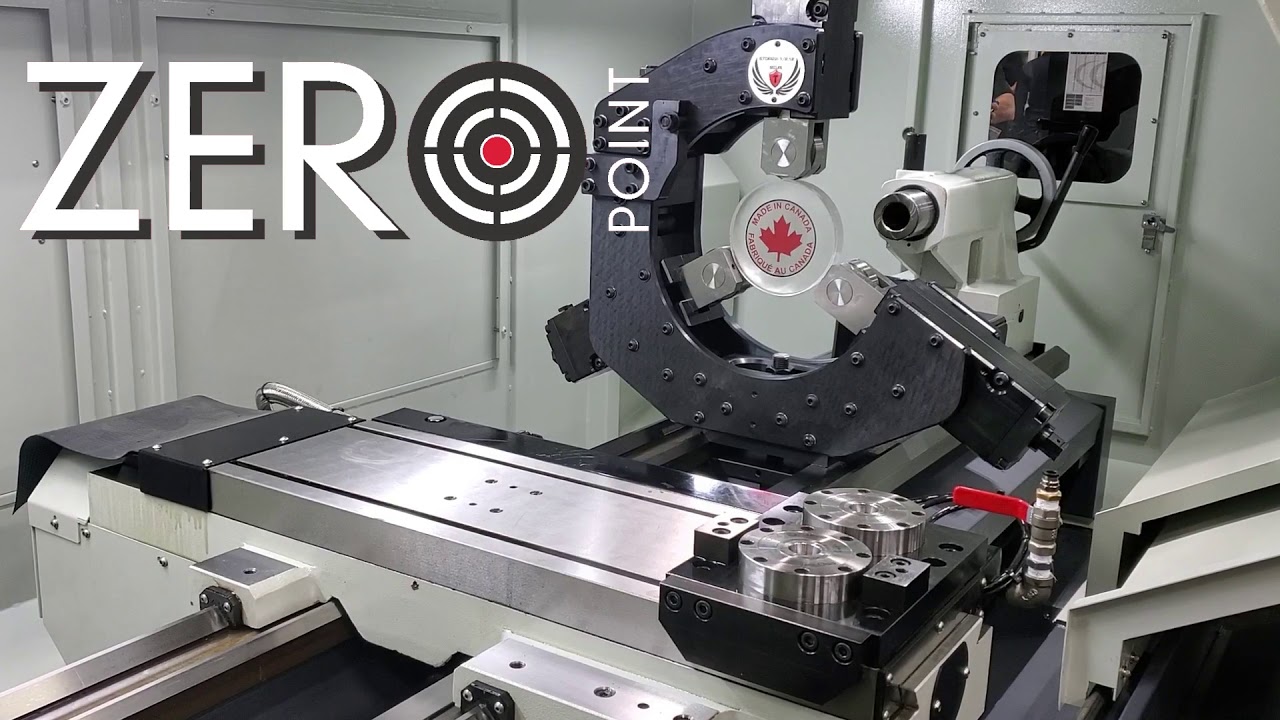

ZERO-POINT

With the ZERO POINT turret’s change system and a Xena lathe, manual machining doesn’t have to mean doing things the old way! This turret quick change system allows to maintain tool offset measurements during the exchange of different drilling and boring accessories. Just like our Xena lathe or milling machine, this system is FAST, EASY AND SECURE.

Broaching a key path VIDEO

When you equip your Xena lathe with the optional pneumatic spindle break option, you will also be able to read the spindle position in degrees on the operator interface, in TACHYON mode.

One spindle rotation will therefore be divided into 1024 positions, which means an approximate resolution of 1/3 of a degree. For a higher resolution for angular positioning , you may also add the “C” axis option. With the “C” axis option, each turn of the spindle will then be divided into 100,000 positions. As an example of application for the spindle brake option, when the spindle break is activated, you may use the “Z” axis of your lathe for broaching operations. The following video shows an example of broaching cycle to cut an internal keyway.